Root Cause Analysis Write For Us

In science and technology, Root Cause Analysis (RCA) is a troubleshooting technique used to determine the root cause of failures or problems. It is generally used in computer operations, telecommunications, industrial control, accident analysis (for example, in aviation, in rail transport or nuclear power plants), medicine (for medical diagnostics), healthcare (for example, epidemiology ) and etc. .

Root Cause Analysis is a process that uses various troubleshooting techniques to determine the cause of a problem. Analysis responds to when, how, and why a problem occurred and is an effective solution to ensure that the problem does not recur. Sometimes the RCA process highlights other areas for improvement in the organization and provides an opportunity to address future issues.

There is no single way to perform a root cause analysis successfully. Instead, it encourages creative and critical intelligence to discover all the possible causes of the original problem. Various tools and plans can be used to solve problems.

How to do a Root Cause Analysis?

1. Identify the Problem

The first stage is to define the problem clearly. It involves identifying what is happening as well as identifying the “side effects” of the problem. Side effects can be caused by severe difficulties and should be treated equally until more information is gathered. Once more information has been collected, side effects can be classified according to resolve.

2. Collect Data

Collecting and taking large amounts of data can be difficult and is often the longest step in the RCA process. Therefore, it makes sense to divide your data collection into phases. You need to gather information immediately about where the problem is occurring, how long it has been happening, and how it affects external factors.

The latter determines the importance of the problem. Examples of external factors are personnel safety, environmental safety, equipment, and revenue. The next step in data collection provides information to analyze cause-and-effect relationships. It includes collecting data on the history of the examined devices or systems, the team members involved, and the organizational plans used.

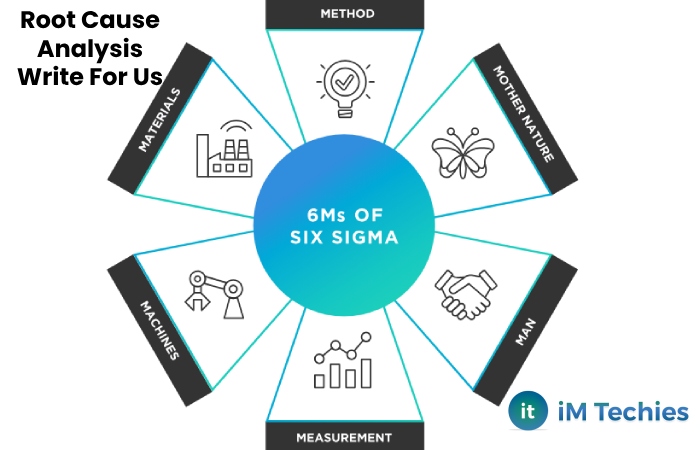

3. Identify the Causal Factors

When researchers are satisfied with the quantitative and qualitative data collected, all possible causal factors are considered. The three leading causes are equipment malfunction or failure, human error, and deficiencies in organizational strategy.

However, it is not enough to complete the investigation of the most obvious causative factor. Problems are typically produced by one or more of these factors and may contribute to the underlying problem.

The easiest way to organize your data and establish causal relationships is to make a visual map. Therefore, cards identify the root cause (s) and the sequence of events that led to the problem. Maps can also show opportunities for future updates.

For example, if the problem identified in Step 1 is related to a hydrotreating unit, analysts can remember corrective actions for subsequent issues in the isomerization or alkylation units.

4. Develop and Implement Strategic Decisions

In the final step of the RCA process, root causes are identified, and analysts begin to make strategic decisions. An effective RCA solution is a multi-part solution that positively impacts equipment reliability, operating costs, the environment, and even the company’s reputation. And also, a practical solution is a solution that rearranges the causal factors of the new strategy.

Take, for example, devices that need to be taken out of service due to irreparable corrosion damage. The main reason found was that the inspection intervals did not correspond to the age of the component. Therefore, solution may be to replace equipment and implement a strategy that redefines inspection intervals at different stages of the equipment life cycle. In addition, engineers, operators, inspectors, maintenance, and management personnel must trained in the new periodic inspections strategy.

Therefore, solutions are unique to each organization. And also, well-known strategy that has been incorporated into many organizational systems Kaizen. Kaizen is more of a philosophy than a strategy, but it encourages the company to improve continually. It means that a series of small actions enhance performance in the workplace. When

How to Submit Your Articles

For Submitting Your Articles, you can email us contact@imtechies.com

Why Write For Im Techies – Root Cause Analysis Write for Us

Search Terms Related to Root Cause Analysis

Pareto analysis

Ishikawa diagram

Fault tree analysis

Failure mode and effects analysis

corrective actions

complex adaptive systems

self-organized systems

cost/benefit analysis

manufacturing.

industrial process control

business activity monitoring

occupational safety and health

systems analysis

risk management

case-based reasoning

causal graph.

ecology, therapy in medicine

environmental remediation

needle in a haystack

7 different root cause analysis techniques

when is root cause analysis required

root cause examples

Search Terms for Root Cause Analysis Write For Us

write for us

looking for guest posts

guest post

becomes an author

guest posting guidelines

become a guest blogger

suggest a post

submit the post

contributing writer

contributor guidelines

guest posts wanted

submit an article

writers wanted

guest posts wanted

Guidelines for Article to Writing Root Cause Analysis Write for Us

For Submitting Your Articles, you can email us contact@imtechies.com